We Completely Sealed Reflective Decals, Protecting Them From Outdoor Debris

- Brand

- OEM

- Concept

An automotive manufacturer required reflective diamond grade decals for their equipment to improve safety and visibility in the field. A common flaw with this reflective material is that once cut, the exposed diamond rows allow debris and water to penetrate, which can compromise the decal’s integrity over time. While this issue is typically contained within the outer roll, prolonged exposure can cause migration of contaminants into the part, leading to performance degradation and aesthetic concerns. They came to us to find a solution.

01_Challenge

Prevent moisture and debris from compromising the durability of diamond-grade reflective decals after cutting.

02_Solution

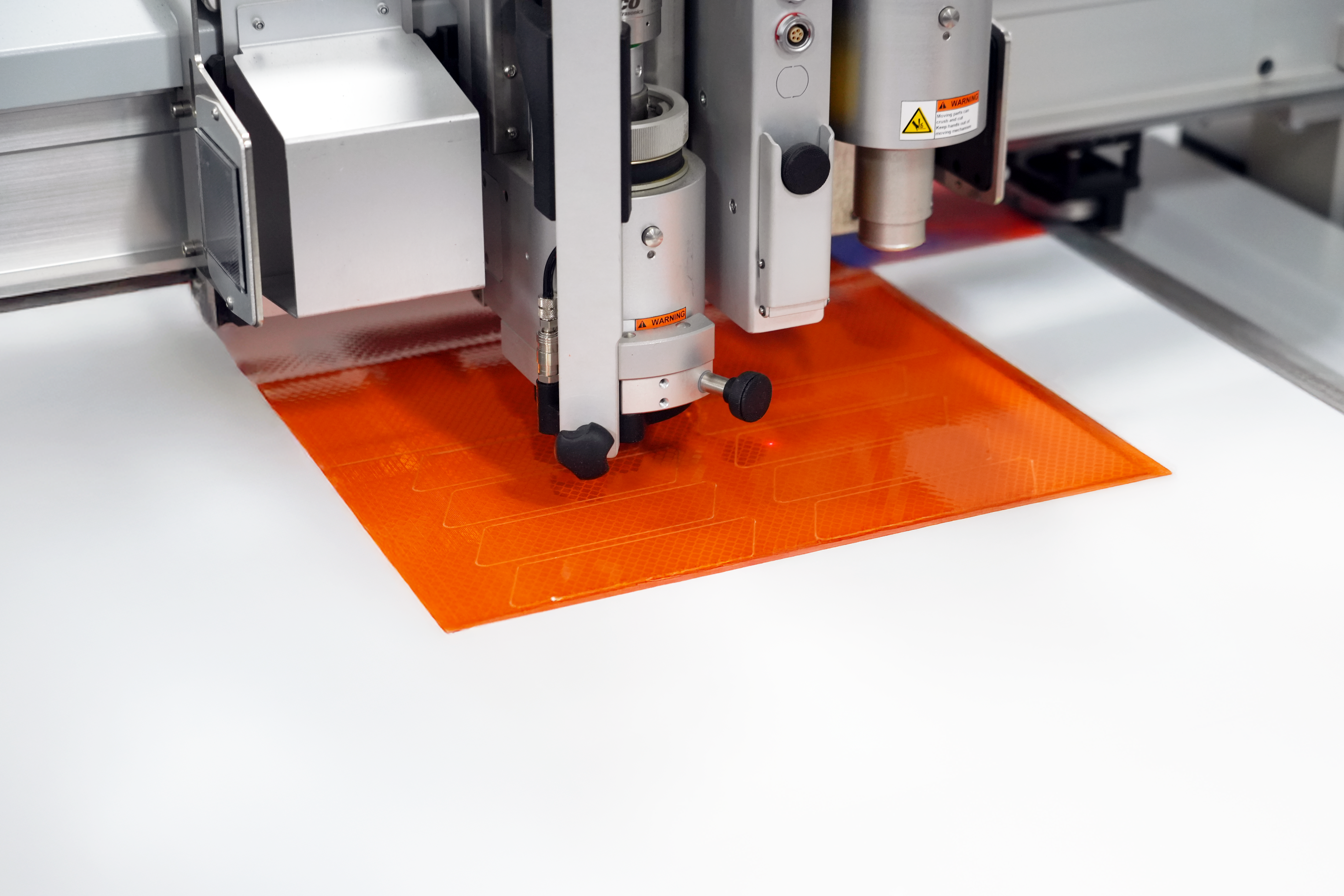

To address this, we proposed an edge sealing process to enhance both the durability and appearance of the decals. By sealing the edges, we could effectively prevent moisture and debris infiltration, ensuring the decals maintained their reflectivity, longevity, and finish.

This process simultaneously cut and sealed the material, eliminating the need for a separate sealing step and reducing costs. After extensive field testing comparing sealed and unsealed decals, the manufacturer concluded that edge sealed decals significantly outperformed their unsealed counterparts.