When it comes to graphics in the dark you have 3 options to choose from, glow in the dark (phosphorescent) printing, fluorescent printing, and reflective printing.

All three of these have their benefits and drawbacks, so the choice ultimately comes down to your environment and specific needs. In this blog post, we’ll take a closer look at glow in the dark ink and substrates, fluorescent ink and substrates, and reflective printing to help you determine which type is better for your needs.

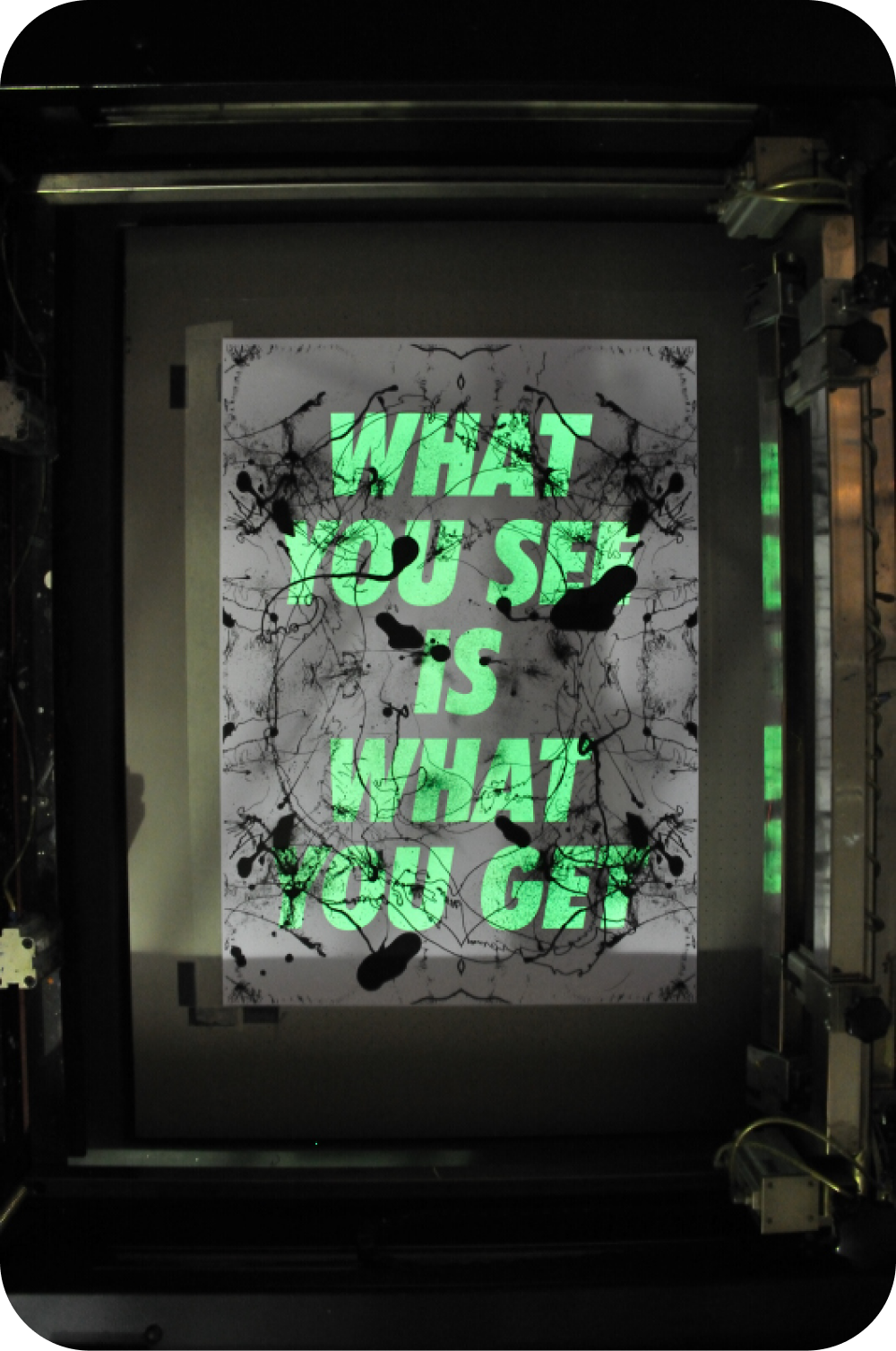

Glow in the Dark Printing

Phosphorescent, also referred to as Glow in the Dark or Luminescent Powders are pigments that absorb light and slowly emit a glow over time. The glow is best seen in darkness or under black-light conditions. Depending on the pigment and pigment load in the ink, the glow may last a few minutes or several hours. This comes in UV-curable and solvent-based ink series.

There are also glow in the dark substrates that can be overprinted with regular (the glow in the dark property would be reversed out print).

Advantages of Glow In The Dark Printing:

- Ease Of Application: This does not require blacklight to be seen in the dark.

- Substrate Employment: This can be used on most substrates.

Disadvantages of Glow in The Dark Printing:

- Versatility: Has a slight green or blue tint to the areas of the design when the ink is inactive (in the light).

- Duration: Powder glow color & duration are not indefinite.

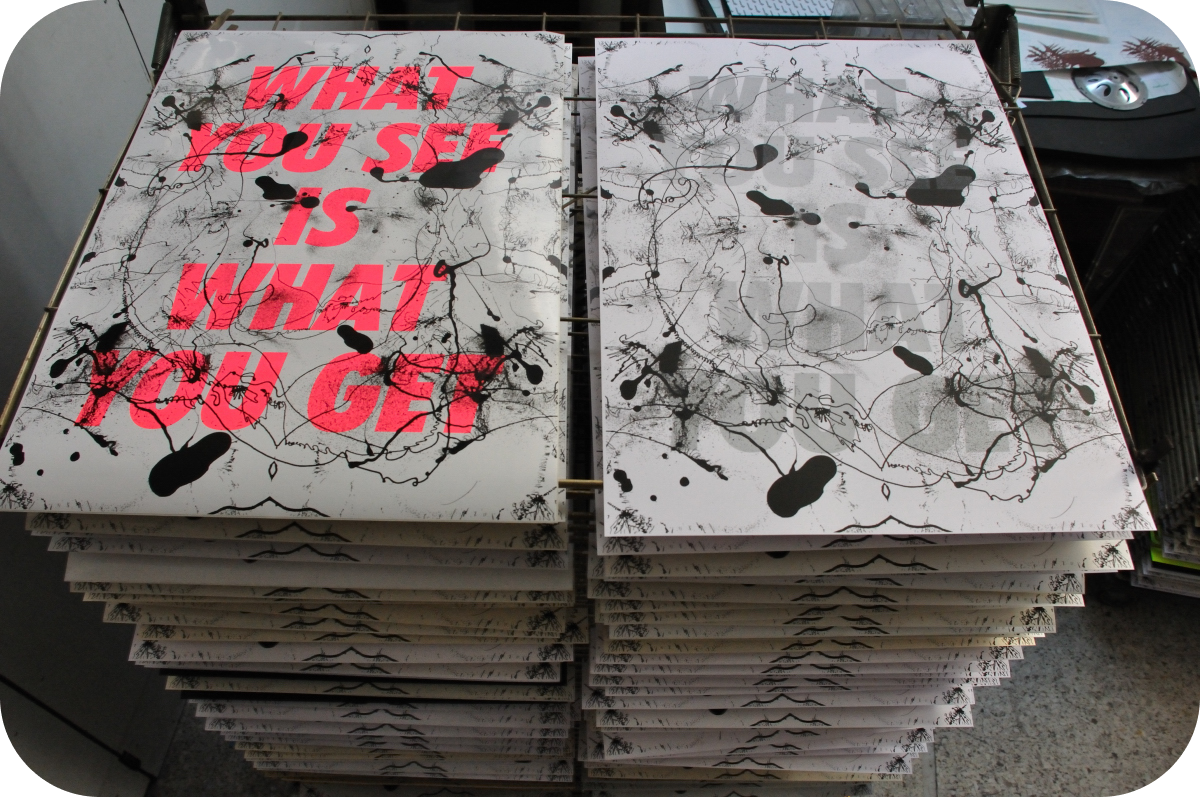

Fluorescent Printing

Fluorescent or neon-printed inks contain pigments that absorb ultraviolet light which then reflects back out. We use these inks heavily for daytime applications and even formulate our own colors to extend the color gamut. They also happen to light up in the dark under black light. If the desired result is for these colors to light up even more in the dark we add an optical brightener to the color process.

You can also overprint on a fluorescent material instead of utilizing fluorescent inks.

Advantages of Fluorescent Ink:

- Substrate Employment: This can be used on most substrates.

- Versatility: Holds the same color when inactive (in the light) and active (dark).

Disadvantages of Fluorescent Ink:

- Ease of Application: Relies on blacklight to activate the color.

Reflective Printing

Reflective printing enhances visibility by reflecting light, making the printed design appear brighter and more noticeable when illuminated by headlights, flashlights, or other light sources. This type of printing is commonly used for safety applications, such as signage, vehicle markings, and equipment that needs to be visible in situations where lighting might be limited. Learn more about substrate options here.

Advantages of Reflective Printing:

- Ease of Application: Highly visible, tested, trusted, and proven by governments, military, and corporations seeking to improve safety.

- Substrate Employment: Can be ink or base substrate.

- Color Versatility: Custom colors

Disadvantages of Reflective Printing:

- Versatility: Requires light pointing at it.

- Application Usage: Mostly used for safety applications.

Final Thoughts

All these methods for lighting up graphics in the dark have their advantages and disadvantages, and the choice between them will depend on your specific needs and preferences. If there is no way to add blacklight to your environment and color variations in the light are not a concern, glow in the dark printing may be the best option. If you need your colors to look the same in the dark and light, fluorescent printing just may be the ticket. If you’re looking to increase safety, reflective printing may best illuminate warnings and hazards. Ultimately, these approaches all offer an effective solution for providing eye-catching visibility of your graphics in the dark.

Grow your company’s revenue while personally enhancing your career! Glow in the dark graphics are awesome, but they take more than good artwork or a well-structured design to entice a consumer to buy a product. It’s a balanced recipe of great design, affordable manufacturing cost, clever placement, and judicious use of resources. Stay tuned for next month’s knowledge drop to learn more!

On the other hand, if you can’t wait or want to cure your glow in the dark graphic issues RIGHT NOW – click here, and we’ll talk today!