How We Hit Extreme Print Resolution On Thick Material?!

- Brand

- Specialty Retailer

- Concept

Our customer approached us with a unique challenge: they needed a small-format, thick tag that would clearly communicate product trim and color while adhering to their products. Their current tags were not printed in a way that preserved fine text or accurate colors, and the part’s delicate details and glossy surface raised concerns about legibility and overall visual quality. Traditional printing methods had clear limitations: litho printing cannot print on rigid substrates and requires high volume, screen printing has excellent color resolution but struggles with small CMYK images, and digital printing is limited by a maximum resolution of 3.5 pL. We were up for the challenge…

01_Challenge

Redesign a small, thick product tag to ensure crisp text and accurate color.

02_Solution

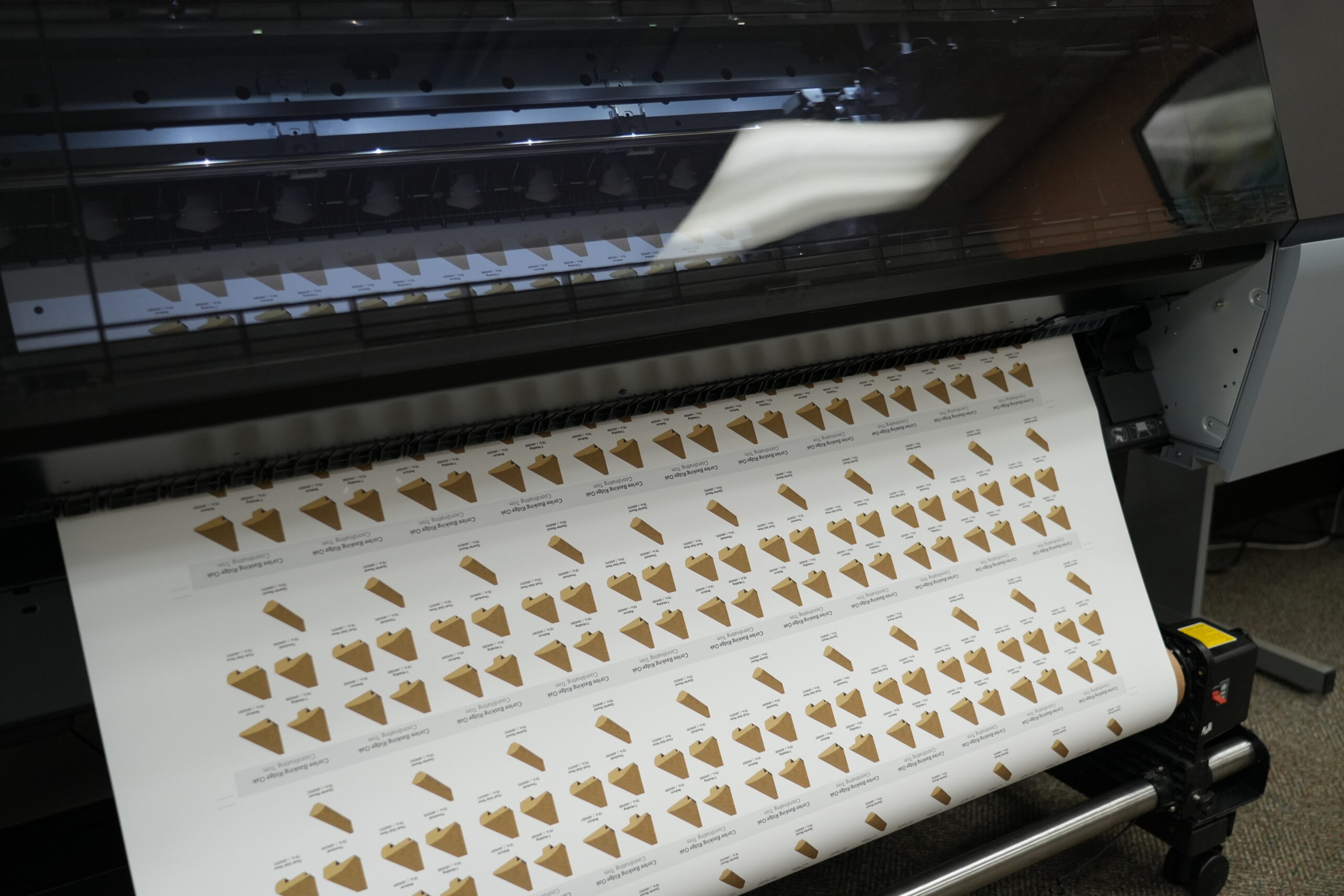

To achieve maximum clarity, we printed the design on high-resolution aqueous printer film, which captured the fine text and subtle color nuances. Since the aqueous printer cannot print directly on rigid foamboard, we laminated the film onto the boards, providing a smooth, stable surface.

To eliminate unwanted glare, we selected a matte film, addressing both clarity and finish in a single step. Finally, we cut each tag precisely and kitted them for individual store delivery, ensuring a seamless application process and consistent, high-quality merchandising across all locations.