There are thousands of special effect inks, laminates, materials, and tools available. How do you know where to start?!

As one of the largest screen printers in the country, we take pride in our special effects printing. From distinctive textures and unusual substrates, to fragrance and metallic colors – we do it all! In this post we will try to break down some of the special effects we offer…

1. Scented

Smell is the strongest trigger of memory, affecting our emotions and even our mood. Therefore, when scent is incorporated within print media, the message becomes more engaging, evoking an emotional response that goes beyond the visual or written message.

Generally speaking, there are two categories of printable scents and how they are manufactured. There are non-interactive scents and interactive scents and you can manufacture them using a print coating (varnish/slurry) or print ink. A print coating is like varnish for wood. It goes over your artwork as a layer of clear scent or fragrance. While scented print ink combines the fragrance with the colored ink that is on your print media. Read our beginner’s guide on scented printing.

2. Soft Touch

Soft touch is a type of printing finish that creates a velvety, matte texture on print substrates. You can achieve this finish through a soft touch ink, soft touch laminate, or utilizing pre-coated soft touch material. Want to know more about the differences? Learn more about soft touch by searching it on our faqs.

3. Chalkboard

Printed chalkboard graphics are a great tool for combining temporary writing and permanent graphics. This is achieved by using a chalkboard screen print ink or base chalkboard material.

4. Dry Erase

Similar to printable chalkboard graphics, dry-erase graphics are also a great tool for combining temporary writing and permanent graphics. This can be achieved with a laminate, or by printing on a base material.

5. Scratch-Off

Printed scratch-off is an opaque ink designed for overprinting. It can be removed easily with finger or coin scrape and does not powder.

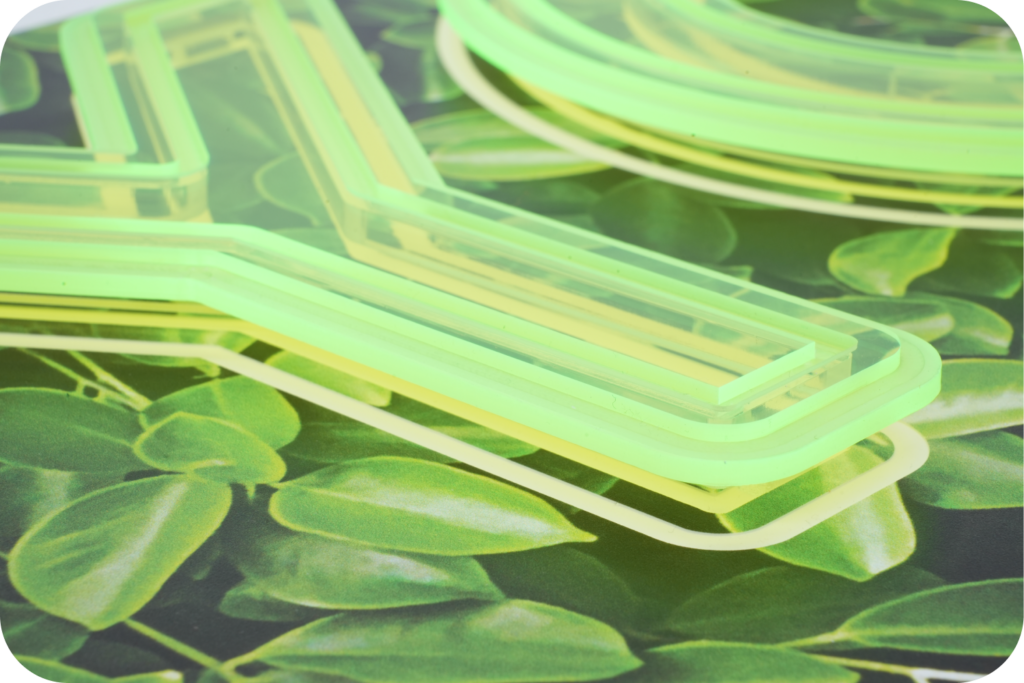

6. Glow in the Dark

Glow in the dark graphics are what they sound like – graphics that are most visible in the absence of other light. The “glow effect” is called phosphors, which absorb light from the sun or high-powered lights and then emit the light, which really pops in a dark room.

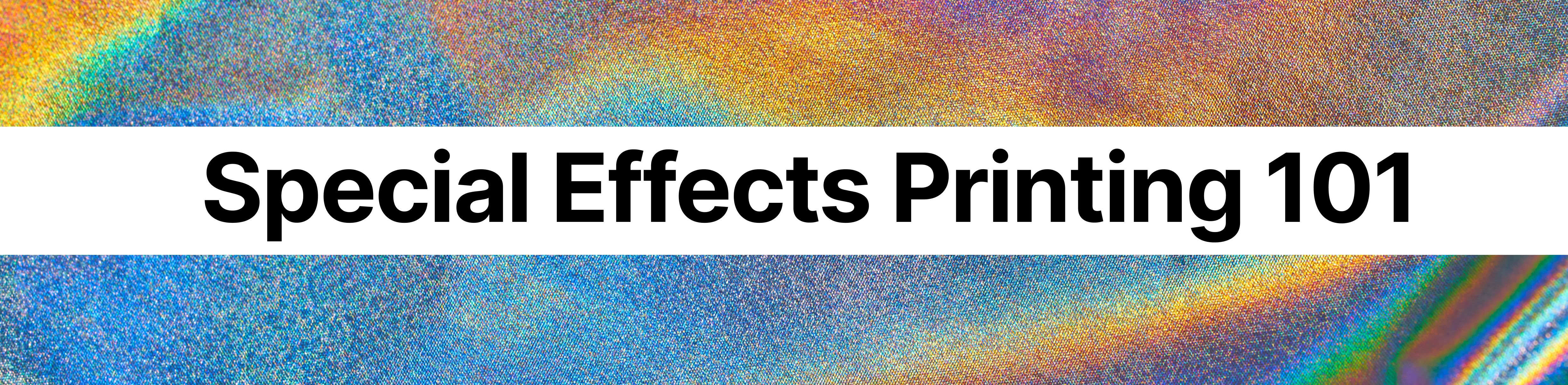

7. Translucent

Translucent graphics or translucent printing is essentially utilizing space, design, and print process to create see-through graphics. YThis is accomplished through using a base translucent material, design, or translucent inks.

8. Glitter

Glitter: the product that is essential in many sparkly Christmas decorations, children’s artwork, horrendous pranks, and special effects printing. Printed Glitter graphics are an assortment of flat, small, reflective particles reflect light at different angles, causing the surface to sparkle or shimmer. There are many different ways to achieve glitter; through inks, adhesives, hand assembly, laminate, or base glitter materials. Glitter inks incorporate slightly bigger flecks, similar to the common glitter flakes, than those in shimmer inks.

9. Lenticular

Lenticular special effects printing utilizes design and lenticular ridges to produce a printed graphic with an illusion of depth, or the ability to change or move as they are viewed from different angles.

10. Pearlescent

Pearlescent printing (coined from natural essence of pearl which also produces the same light-refracting effect) creates a colorful and vibrant shimmering pearl-like impression on any printed graphic. The pearlescent effect is created from water based, solvent based or UV coating pigments structured with transparent layers. Their different refractive indices and optical wavelengths amplify or absorb light depending on their thickness, creating the iridescent sheen.

Using a discrete particle of a shimmering pearlized compound with the right base, we can print pearlescent in many different hues for your project.

11. Mirror

Printed mirror special effects are similar to metallic and chrome special effects but are much more smooth. Typically this is accomplished through lamination and then printing, or by printing over a base mirror material.

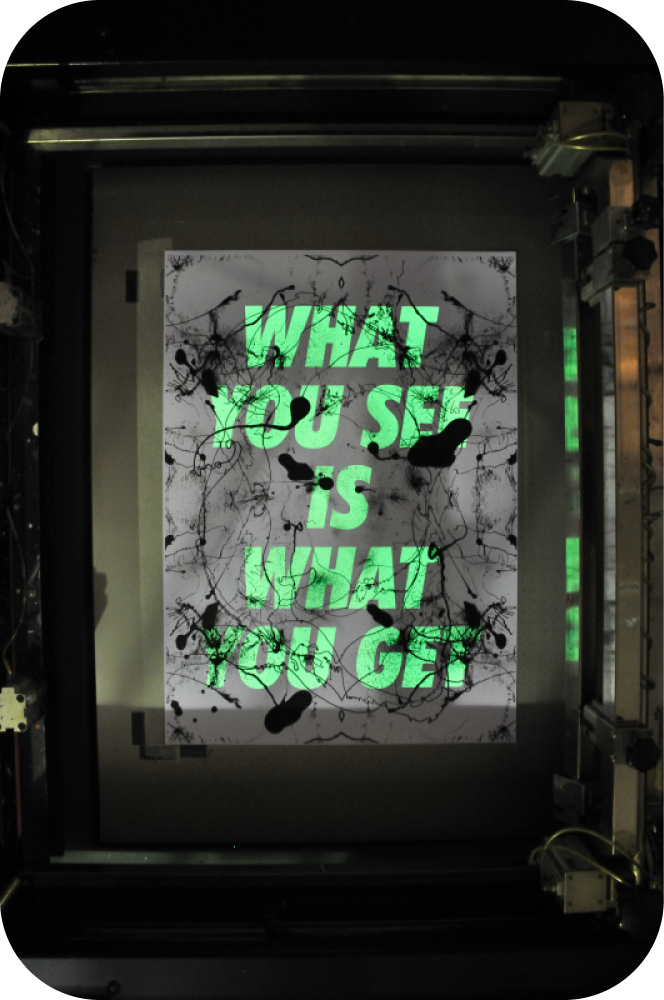

12. Metallic

Metallic special effects printing is similar to pearlescent but is applied to metallic colors like silver, gold and bronze. This finish is achieved through inks, coatings, hot and cold foil stamping, foil laminations, and/or base metalized material. We recommend using spot print if the desired result is in specific precise areas (reducing waste and saving time).

13. Chrome

Chrome special effect printing typically refers to a technique which applies a layer of metallic or chrome-like ink to printed materials. This process creates a shiny and reflective appearance similar to polished metal, adding a unique and eye-catching effect to the printed piece. This finish can be attained through inks, coatings, hot and cold foil stamping, foil laminations, and or base metalized material.

14. Edge Lit

Our edge lit graphics are made with a fluorescent acrylic that uses natural light to illuminate itself, without needing any power input. On this versatile, glow-emitting material we can print, route, drill, laser etch, and form (heat bend into 3D shapes) to create unique and distinct marketing touch points.

Read more about Edge Lit Graphics.

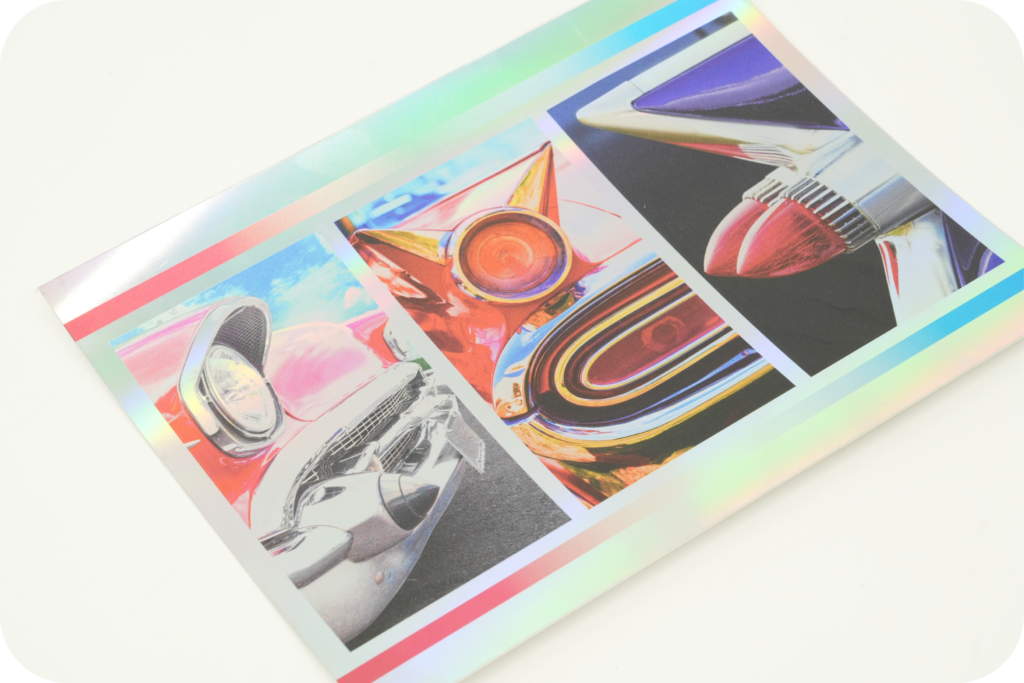

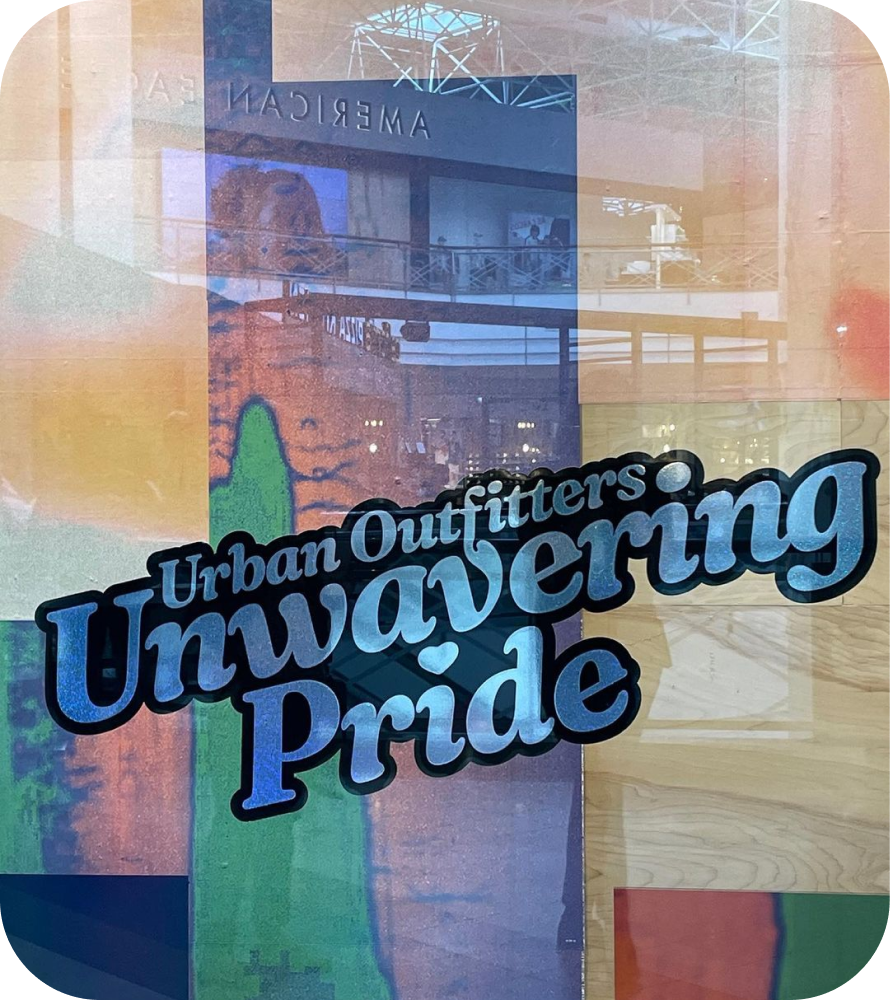

15. Holographic

The printed hologram special effect is created by metalizing the surface substrate with a thin layer of shiny silver aluminum. The surface diffracts the light into many colors and reflects the light. This look can be achieved through lamination, printing on a prizmatic base material, or metallic screen inks.

16. Prismatic

Similar to holographic printed special effects, printed prismatic special effect is created by metalizing the surface substrate with a thin layer of shiny silver aluminum. The surface diffracts the light into many colors and reflects the light. This look can be completed via lamination, printing on a prismatic base material, or metallic screen inks.

17. Fluorescent Spot Color / Neon

Fluorescent or neon-printed colors are super bright because they contain pigments that absorb ultraviolet light that then reflects back out. Neon inks are printed as spot colors – a pure color in its own right, rather than created with four color process (CMYK) printing. This special effect is achieved through inks, lamination, or base material. We like to say if your eye can see it, we can hit it.

18. Matte + Gloss / Spot Gloss / UV Spot

Spot coating is the technique of applying a high gloss, semi-gloss, or matte gloss to a selective area on a printed piece, rather than coating the entire sheet. This draws attention to the specific portions of the artwork – even if it is the same color as the background.

UV Spot coatings are cured with UltraViolet light, resulting in a deeper more vibrant look than conventional coatings.

19. Raised Surface / Heavy Deposit Clear

Similar to a spot UV we can control the timing of exposure to the UV light and varying screen making parameters, we can also create raised profile gloss and matte coatings, which give dimension and texture to these effects. We can also get this texture by printing on a textured base surface or by printing second surface on a clear raised surface.

20. Thermochromic

Printed thermochromic special effects change color based on temperature, often being used for mood jewelry, toys, and sticker thermometers. The ink we use is a type of dye that changes color when temperatures increase or decrease. It is a great way to add a little interactive element to your graphics!

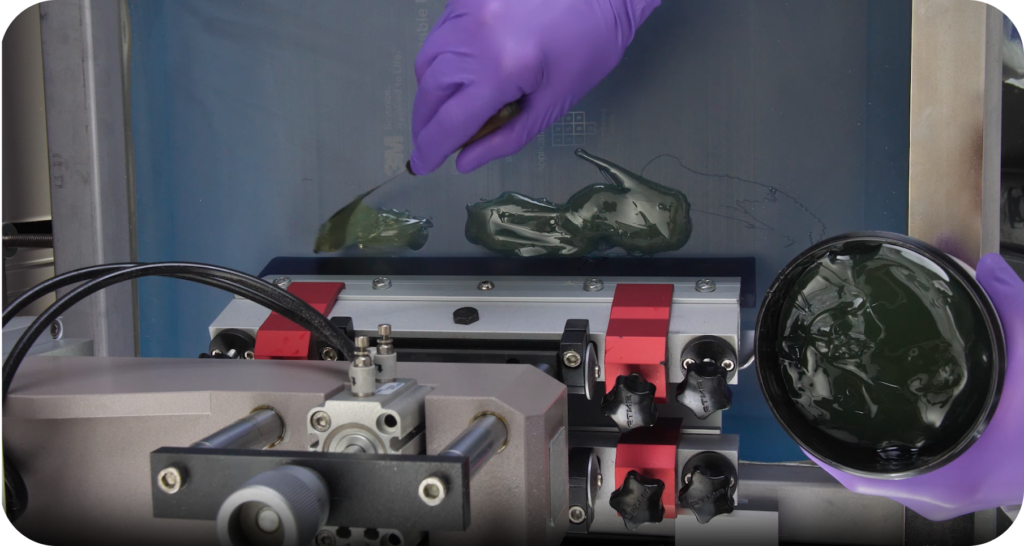

21. Hydro Dip / Hydro Graphics

Hydro dipping, also known as water transfer printing, hydrographic printing, or immersion printing, is a method used to apply intricate patterns and designs to completely wrap three-dimensional objects. We first print on a hydro-dip film, clean the part, apply the film onto water, dip the part into the water, dry, and finally apply a clear coat to the part. This a popular technique used for dimensional signage, automotive parts, electronics, sports equipment, firearms, and more.

22. Custom R&D

Don’t see what you’re looking for? We specialize in customization and help develop new and unique printed products for our customers every day.

Honorable Mentions…

23. Antimicrobial

Antimicrobial film is a type of film or coating that contains substances that inhibit the growth and spread of harmful microorganisms such as bacteria, viruses, and fungi. The antimicrobial properties of the film are designed to protect the surface or material to which it is applied, reducing the risk of contamination and providing a hygienic solution for a variety of applications.

The film works by releasing antimicrobial agents that kill or inhibit the growth of harmful microorganisms. These agents can be a variety of substances, including silver ions, organic acids, or other active ingredients that have antimicrobial properties.

Antimicrobial films can be used in a variety of applications. For example, we have applied antimicrobial film to print media, countertops, table graphics, table easels, and touchscreens to prevent the growth of harmful bacteria and other microorganisms. Read how we were able to wrap an NFL stadium’s tables in less than 48 hours.

24. Reflective

Reflective printing enhances visibility by reflecting light, making the printed design appear brighter and more noticeable when illuminated by headlights, flashlights, or other light sources. We print this effect by using reflective materials, or inks that can reflect light, especially in low-light or dark conditions. This type of printing is commonly used for safety applications, such as signage and equipment that needs to be visible in situations where lighting might be limited..

25. Anti Slip

These can be as basic as custom-sized stair treads, or branding and advertising non-slip patches in indoor and outdoor aquatic centers. Anti Slip graphics are often used for branded foot-landing steps on lawn, construction, and agricultural equipment. Learn more here.

26. Adhesive

There are obviously many different ways to apply adhesive, however did you know we can print adhesive too?

Screen printable adhesives allow us to apply adhesive directly onto a part with bond lines as narrow as 0.5mm. Why do this instead of tape or other adhesive methods? It results in more product versatility and increases efficiency by reducing the need to order assembly tooling, die-cut parts, and extract waste. Learn more here.

Grow your company’s revenue while personally enhancing your career! Special effects printing is awesome, but it takes more than good artwork or a well-structured design to entice a consumer to buy a product. It’s a balanced recipe of great design, affordable manufacturing cost, clever placement, and judicious use of resources. Stay tuned for next month’s knowledge drop to learn more!

On the other hand, if you can’t wait or want to cure your special effects printing issues RIGHT NOW – click here, and we’ll talk today!