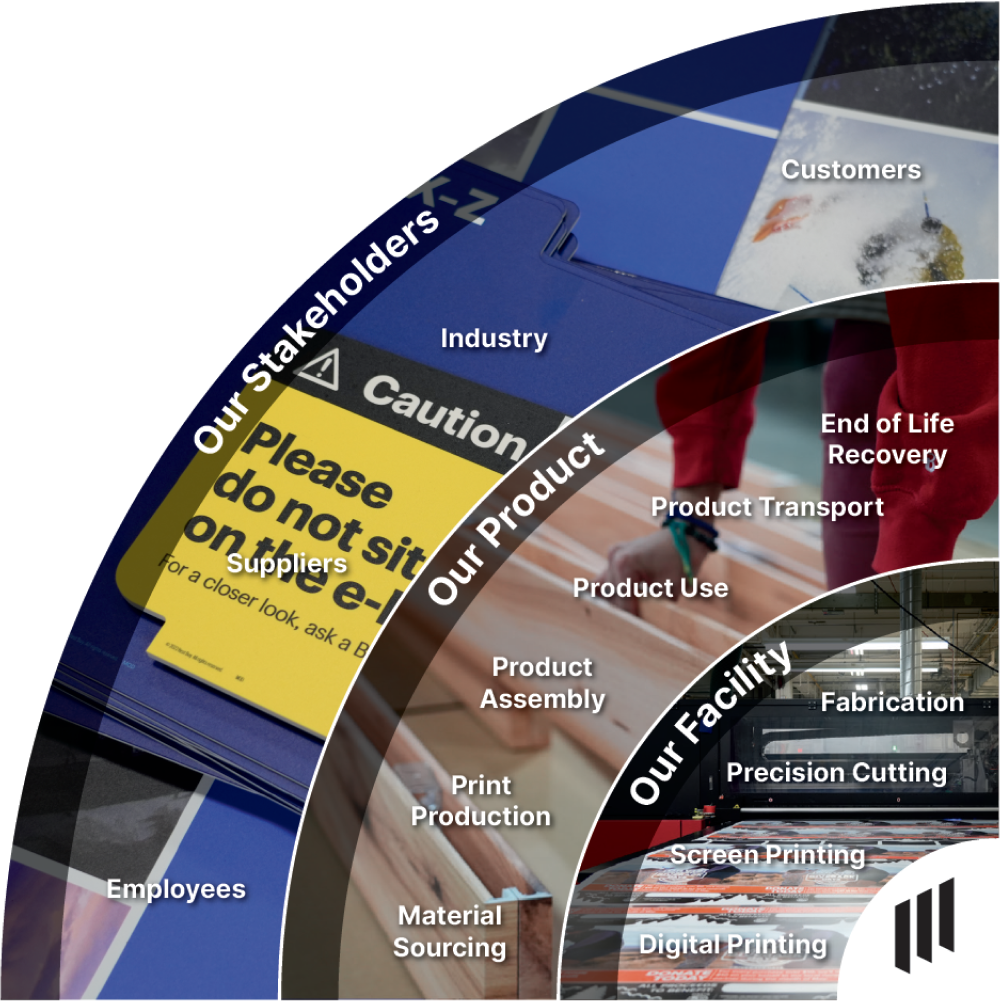

We remain committed to our mission to drive value for our clients by providing expertise, superior products, and dependable services with speed and precision. And we’re equally committed to doing so in a manner that doesn’t deplete the earth’s resources. This commitment acknowledges our responsibility for our entire value chain—which extends across our facility and through the entire life cycle of our products. And it drives our strategy— whether innovating solutions to environmental challenges or creating opportunities for customers to use sustainable materials or providing assistance to our community. We’re striving to enable the type of world we want to live in.

By engaging with others in our environmental work, we can achieve an even greater impact. We learn from feedback and we work with partners to influence change in our industries. This is why we want to share some big wins from this year. Be sure to read the full report here.

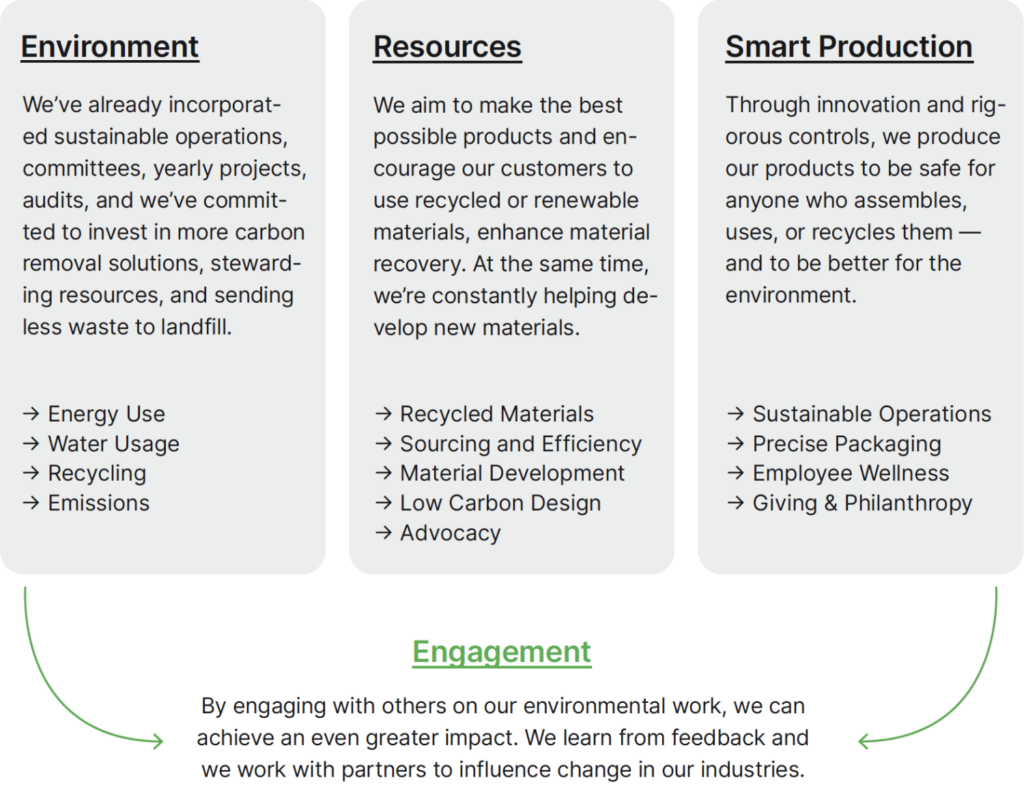

Our Environmental Strategy

The environmental challenges the world faces today are significant, and Modernistic is responding with urgency and dedication. We approach our work by focusing on fundamental questions. What matters most? Where can we make the greatest impact? These questions inform our goals to achieve change and guide our initiatives across the strategic pillars of environment, resources, and smarter production. We know we’re not alone striving to reduce our environmental footprint. So we engage with others to support our efforts and find opportunities to lift our local community along the way.

Our Goals

We increase value for our clients by providing expertise, superior products, and dependable services with speed and precision. And we strive to do so in a way that sustains the planet and the resources that we all depend on. Setting ambitious goals is essential to this — to drive the innovation and collaboration that makes change possible and to be transparent and accountable for our progress.

1. Our Customers Are Committing to Carbon Neutrality!

Our goal is to one day achieve independence from nonrenewable and nonrecyclable materials. As we progress toward this objective, we’re doing so without sacrificing the quality, look, and durability of our products. We’re working on innovations in recycling to enhance material recovery and support circular supply chains for ourselves and our customers. With the growth of corporate commitment to carbon neutrality, many customers are expanding their investment in sustainable alternative material purchases. Read more about our material supply chain on Page 27.

2. Our Suppliers Are Committing to Creating Recycled Products and Recovery Options!

Modernistic’s responsibility for our products begins with the design process and carries through end-of-life. Multiple alternative materials are investigated every time we quote a project. With the increased demand for recycled goods, material suppliers are expanding their investment in development of new materials. And they are creating infrastructure for easy material recovery. Read more about our material sourcing on Page 28.

3. 40% Overall Water Reductions Across Our Facility!

Water is essential to our operations and product manufacturing. Due to concerted efforts (or initiatives implemented) we have reduced our consumption by over 500,000 gallons per year, for the past three years. Read more on our water reduction programs on Page 20.

4. 45% Overall Energy Reductions Plant-Wide

Our energy efficiency goals extend well beyond our products. We’re focused on using less energy across our operations, beginning with how we organize, operate, and maintain our facility. And we continue these same efforts in our supply chain, benefiting our suppliers’ communities by drawing less energy from electrical grids — many of which still rely heavily on fossil fuels. This reduces local air pollution and improves air quality for nearby communities. In 2022 we installed new light fixtures across our facility which led to over 345,000 kWh saved per year. Read more about our energy reduction programs on Page 18 or what we did with our 2022 Continuous Improvement Project on Page 44.

5. We Are Continuing Innovation On Material Recovery

Sending materials to landfill makes poor use of the world’s resources, while also contributing to emissions. This is why we’ve made waste reducing operations a priority. This year we achieved 100% on-site waste separation approximately 1000 pounds of material every day, through recycling and source separation efforts. Read more about material recycling programs on Page 16.

6. Implementation Of Emissions Reporting & Reduction

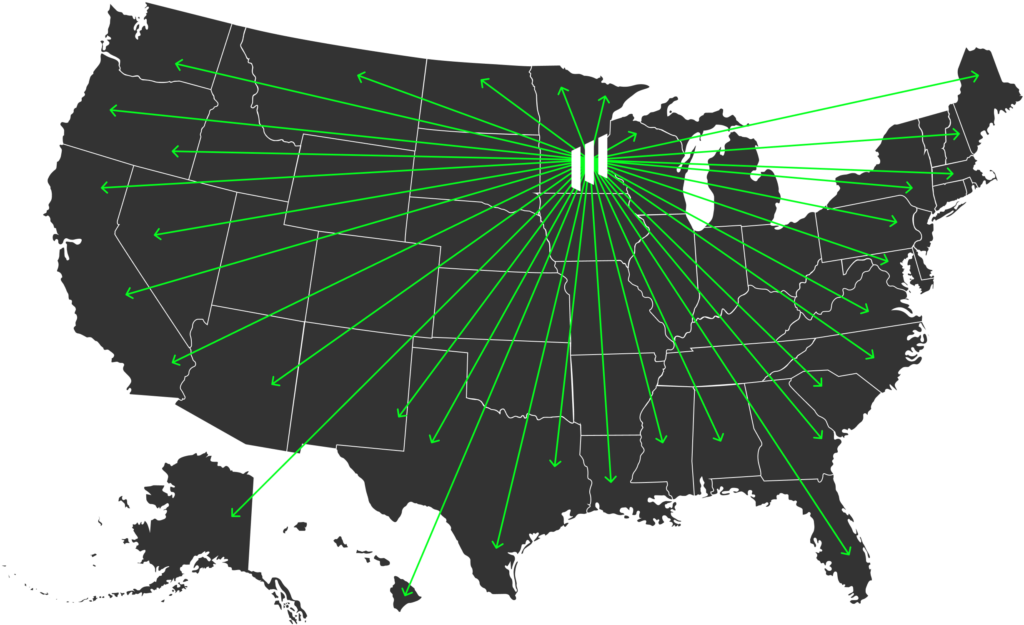

Some materials that are integral to our products result in significant emissions. The same is true for certain manufacturing processes and the transportation of our products. To address these emissions we seek technological solutions, investing in renewable energy, and switching to low carbon modes of transport. In the last 2 years, we have reduced our personal fleet emissions by over 95% and reported 100% of our facility emissions. Read more about our emission responsibility programs on Page 22.

7. More Products With More Recycled Content

Our products rely on the availability of high-quality materials. We’re increasingly sourcing more of these valuable commodities from circular supply chains, drawn from recycled content and renewable resources. This year we partnered with a customer to produce a sustainable package filler that won over 4 national environmental innovation awards. Read more about our material usage on Page 27.

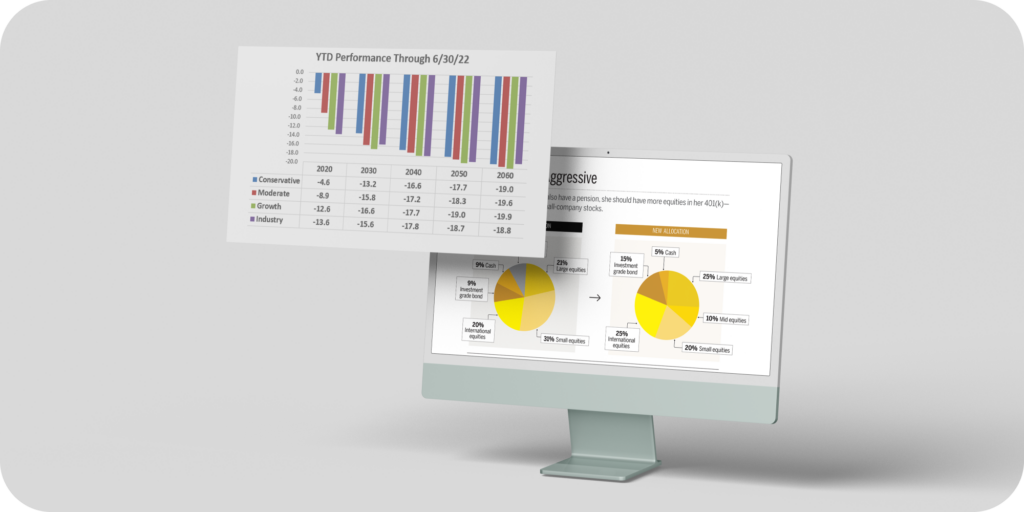

8. 401k Investing Classes For All Staff

We are invested in the success of our staff. This year we offered PTO for our employees to attend 401k investment classes and free 1-1 advising meetings at Mod. We set a goal to achieve 95% participation in our 401k matching program. Read more about our employee wellness on Page 43.

9. Introduction Of Material Of The Month

This year we implemented an email campaign that highlights a new material to over 8,000 print buyers each month. Sign up for it here or read more about our material advocacy, promoting environmentally friendly solutions on Page 30.

10. 2022 Sustainable Green Printing Audit Completion

This year we successfully completed our yearly audit, maintaining our 12th annual certification as a sustainable green printer. Read more about our SGP Certification on Page 37.

11. Removed 60% Of Void Fill With Custom Packaging

We’ve made significant progress towards eliminating empty space and plastic bubble in our packaging. We invested in a bespoke box maker that helps us with precise kitting, reducing the need for wasteful void fillers and shipping costs for our packaging. Read more about how we innovate packaging to reduce our footprint on Page 41.

12. Nonprofit Gratis Printing Program

We value organizations that make a difference in the lives of others and get excited when their needs align with our services. This year we were able to support multiple non profits with their large format graphics at no cost. Read more about our giving mission on Page 44.

13. Supported 10 Renewable Material Projects

Material supply partners value Modernistic because they have been trusting us with their material development for the last 60 years. We take pride in our print and finishing expertise and the resulting industry respect for solving difficult problems. This is why we have a customer retention rate of over 99% – some of which are our own competitors. In 2021, we created a proprietary sustainable magnetic receptive process/product that is more cost-effective than the standard alternative. Read about our material development programs on Page 29.

Read Our Full 2023 Sustainability Report!

Grow your company’s revenue while personally enhancing your career! Sustainable printing is awesome, but it takes more than good machinery or a well-structured design to accomplish a responsible supply chain. It’s a balanced recipe of many resources. Stay tuned for next month’s knowledge drop to learn more, or dive deeper by reading our full sustainability report below!

On the other hand, if you can’t wait or want to cure your sustainable printing issues RIGHT NOW – click here, and we’ll talk today!