Have you ever been asked to request an ink drawdown, press check, or color drawdown? These are all print industry terms for the same thing. Essentially, an ink drawdown is testing how the colors appear on the material you want to use. Think of it as a paint sample you would get when deciding what color to paint your room. Except, in an ink drawdown you are also testing the material it is on as well.

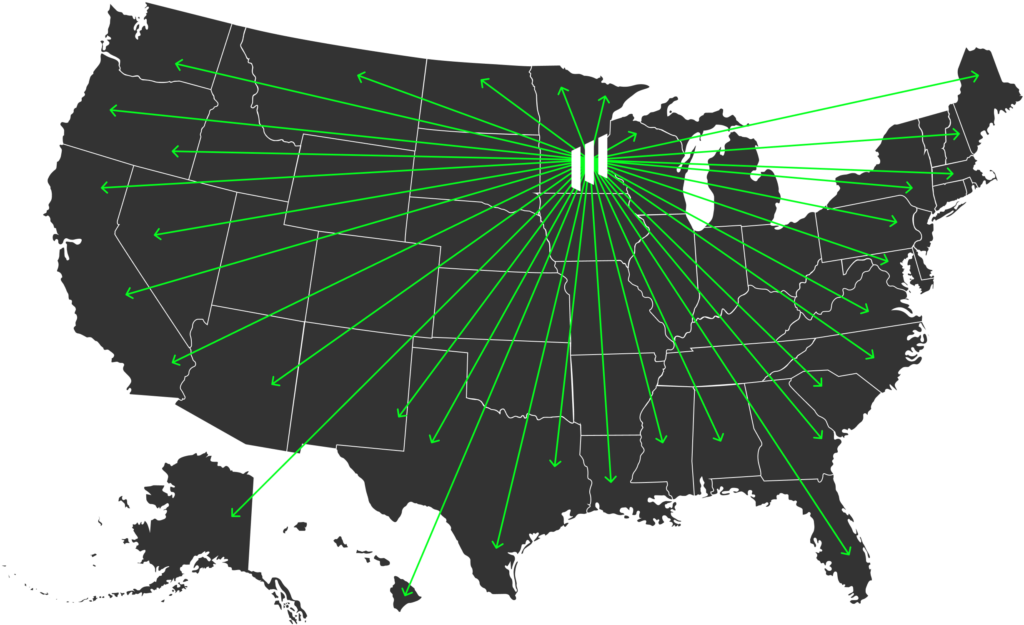

These samples are important because ink is extremely capricious and will be affected by even the smallest changes (like a change in the material). Understanding these changes will help us create an updated ink recipe to combat those changes so that the ink on the new substrate looks exactly how you want it to. Knowing how the colors will react to the material before performing a full production will also decrease chances of rework and cost. This is why we always perform internal drawdowns even if our customers do not request one. This is not always the case for printers and print management companies, make sure to advocate for yourself or utilize an attentive printer. We are extremely confident to say that we have the best ink formulation team in the nation so if you have any questions feel free to contact us.