Looking to add some holiday spirit to your environment? Printed Christmas trees offer a unique and innovative twist to the traditional holiday decor, bringing a touch of modern creativity to festive celebrations. These artificial trees, adorned with vibrant and intricate prints, can showcase a variety of designs, ranging from classic holiday motifs to contemporary and personalized themes.

Printed Christmas trees are not only visually striking but satisfy some people’s reluctance to cut down a live tree. And many are sustainable for year after year use. Additionally, they provide a customizable canvas for individuals and families to express their unique style and preferences, allowing for a personalized and memorable holiday experience. With the convenience of storage and reuse, printed Christmas trees offer a sustainable and aesthetically pleasing alternative, catering to those who seek a blend of tradition and innovation in their seasonal decorations.

After running thousands of holiday projects for major brands – here are 33 Christmas tree designs we think you should know about!

1. Octagonal Curved Tree

This tree uses 8 sheets of material that interlock into one another, with a small base to add stability.

2. Coinciding Triangular Tree

Interlocking triangles create this cool dimensional tree. The assembly is not complicated and can be easily installed in-store.

3. Flat Die-Cut Tree (With Hidden Base)

Need large quantities of trees at a fraction of the price? Nothing beats a perimeter die-cut with no assembly required and a hidden base!!

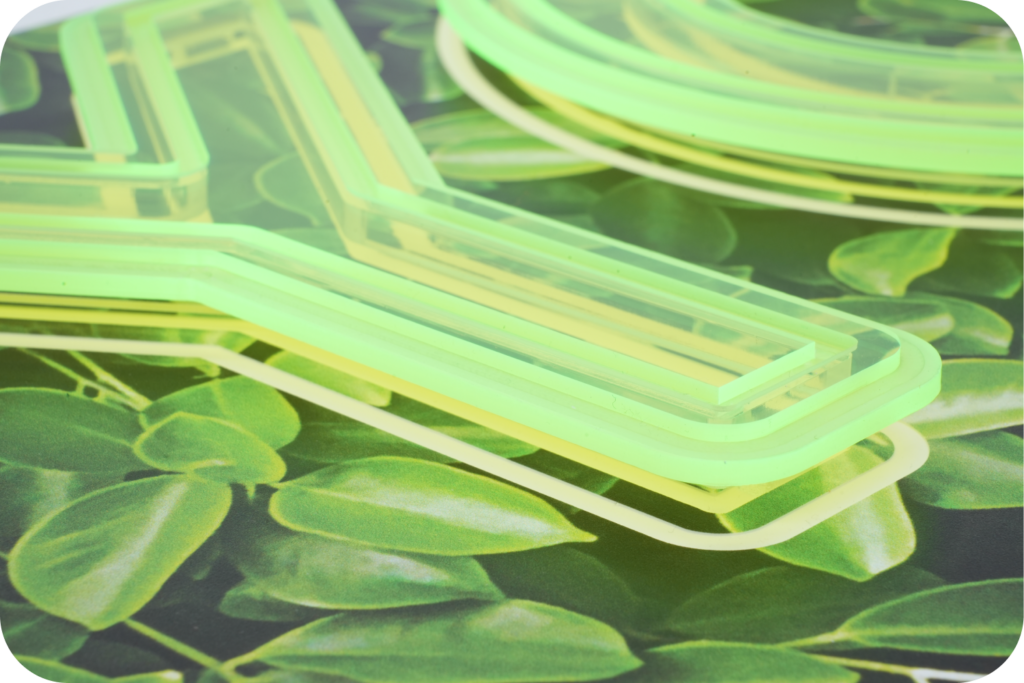

4. Dimensional Acrylic Tree (Product Holding)

This tree used 2 pieces of edge lit acrylic that vertically interlocked into each other, while the 4 intricately cut shelves interlocked horizontally.

5. Scandinavian Tree

This unique tree only requires a flat sheet of material with an interior interlocking pattern!

6. Routed Flat Tree

A classic and clean look, this was routed with 25mm Sintra. It slid into a PVC base.

7. Simple Interlocking Triangle Tree

This version was digitally printed on 1/4″ falconboard to be easily assembled by store associates!

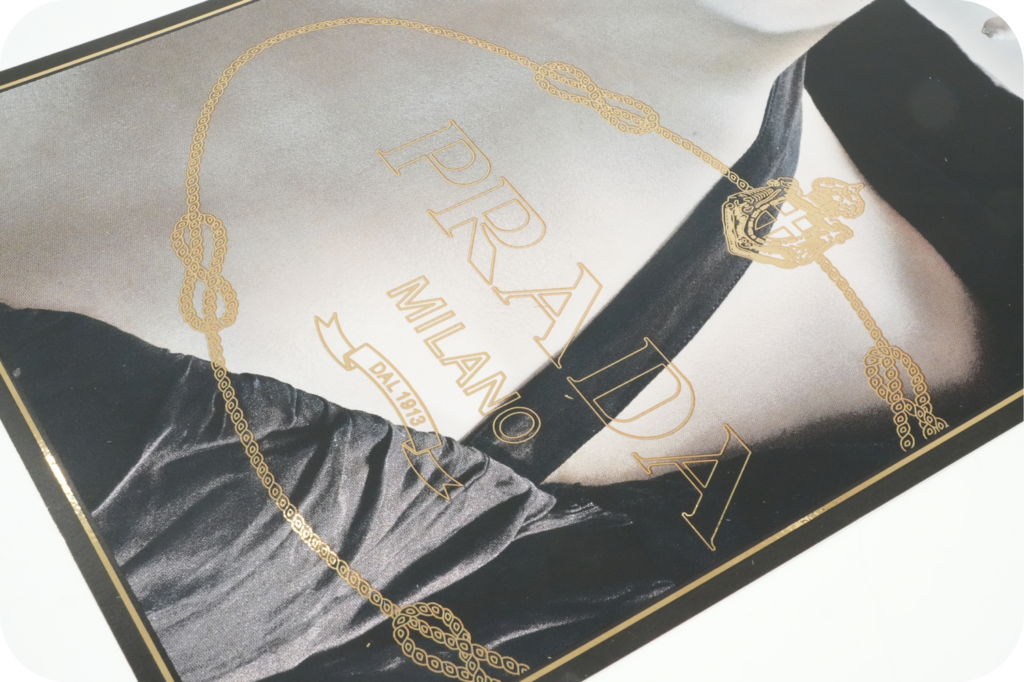

8. Stackable Angular Tree

This style of tree was routed with 2mm Dibond. For extra “pop” we laminated it with chrome and screen printed on top of it!

9. Classic Christmas Tree Product Display

A classic shelf POP Christmas tree display that has been successfully implemented for years!

10. Flat Adhesive Backed Tree

This version utilizes printed Dispa that attaches to each other with strip tape. Base added for stability.

11. Christmas Tree Display

Need to hold a lot of product? This display uses clear post screws, gloss styrene and corrugate in the shape of a Christmas tree to do just that!

12. Interlocking Acrylic Tree

This version used routed edge lit acrylic to join into itself.

13. Pillowed Polycarbonate Tree

This tree used die-cut crease scores in polycarbonate to create a “pillowed” look. Interior structure needed for stability.

14. Coinciding Tree With Star & Adhesive Backed Ornaments

This version had no print, just die-cutting falconboard.

15. Flat Standee Tree With Cutouts

This tree uses a die-cut flat sheet with interior holes. The rectangular base is also out of the same sheet.

16. Quad Tree With Interior Connectors

Instead of parts sliding together, this utilizes interior pieces cut from the same material to hold the sides together.

17. Twelve Part Backlit Tree

Achieve this stunning look with 12 interlocking die-cut trees of various sizes with 30pt cardstock.

18. Complex Self-Engaging Tree With Ornaments

This version was screen printed and die-cut on corrugate. Interior base is needed to provide stability.

19. Interlocking Tree (Product Holding)

This version uses 4 trees that fit together vertically, with 2 shelves connecting horizontally.

20. Heat Bent Based Flat Trees

This style is routed Sintra with heat bent bases.

21. Interlocking Heat Bent Angular Tree

This version utilizes heat bending and interlocking parts on gloss ABS plastic.

22. Tri Shelf Interlocking Tree

Designed for 3 vertical interlocking trees with 3 horizontal engaging shelves.

23. Dump Bin Tree

Classic dump bin construction with a reinforced base in the shape of a tree.

24. Interlocking Triangular Tree

For a simple installation, this uses 8 interlocking die-cut triangles of various sizes.

25. Heat Bent Shelf Tree (Product Holding)

Designed to hold heavier items, this shelf uses heat bent acrylic held together with post screws.

26. Complex Rigid Interlocking Angular Tree

Manufactured with 12 printed MDF wood interfacing trees, with a square base.

27. Stacked Pyramid Tree

This version utilized 4 stacked pyramids with crease scores to provide dimension.

28. Shaded Dimensional Stacked Tree

Very similar to the stackable angular tree, this uses shaded printing on the interior sides to trick the viewer into seeing an additional dimensional plane.

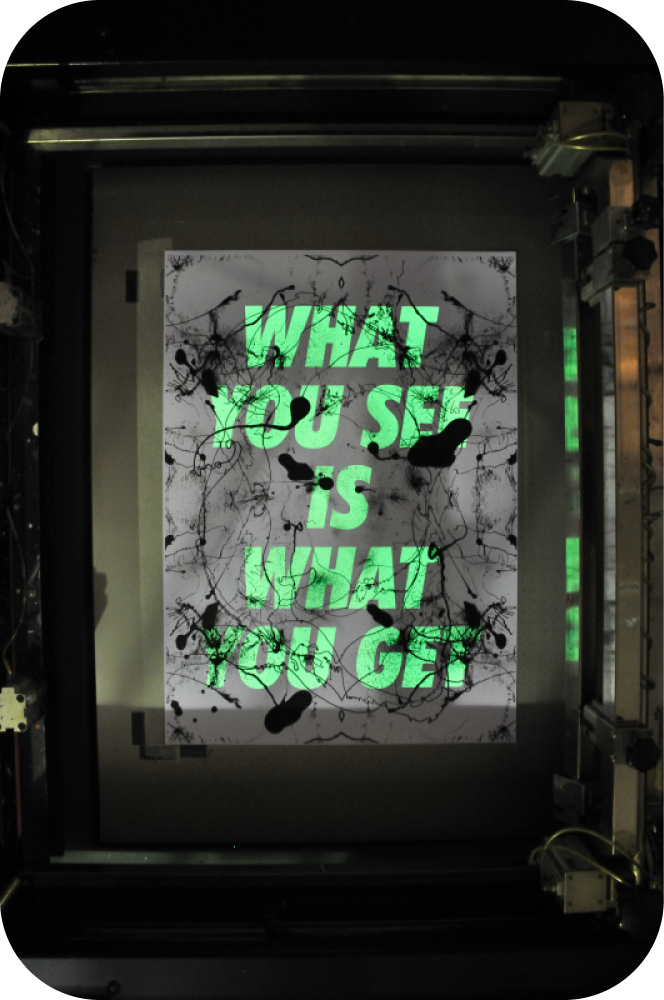

29. Double Interlocking Tall Tree

This version uses second surface screen printing on clear 5mm acrylic.

30. Stacked Cone Tree

This design uses printed styrene formed into cones with strip tape.

31. Creased & Stacked Angular Tree

This version uses the angular tree design but stacks itself on the opposite edges to give more dimension. An interior interlocking base is required for stability.

32. Die-Cut Lettering Trees

This design uses thru-cuts and crease scores to form lettering for a fun message. Always requires interior base for stability.

33. Accordion Tree

Designed to ship efficiently this tree accordions up and down. Can’t beat cost-effective and easy to install!

Grow your company’s revenue while personally enhancing your career! Christmas tree displays are awesome, but they take more than good artwork or a well-structured design to entice a consumer to buy a product. It’s a balanced recipe of great design, affordable manufacturing cost, clever placement, and judicious use of resources. Stay tuned for next month’s knowledge drop to learn more!

On the other hand, if you can’t wait or want to cure your display issues RIGHT NOW – click here, and we’ll talk today!